Eco Tank & Flare Stack

Eco Tank*

Last line of defense preventing “fines” from entering the flare stack.

Flare Stack with Venturi Line*

Negative pressure to evacuate hazardous gasses away from the rig

*INCLUDED IN THE SEPARATOR PACKAGE

Eco-Tank - 12"

- Vessel is a coded Section 8 ASME vessel

- Unit is installed inline with the vent line to mitigate the release of water/dust/cuttings material through the flare stack during normal drilling operations.

- Unit has the capability to have sensors installed that can monitor the tank level as well as the pressure on the unit during use. These sensors also have the capability to be monitored through the Pason/Totco system on the rig

- If monitoring indicates the level is to high, a 4” drain is available to use to empty the unit

- Also installed on the unit is a 150psi pressure-safety valve (PSV); in the event a portion of the vent line or the unit itself is plugged off by unforeseen material. This PSV will allow any pressure build-up in the system to be vented to atmosphere.

- Also available is an 8” vent line system- most seen size in the air-drilling industry, however, this vessel is not coded; but these vessels are inspected by a third-party inspection company and are certified under API 510 standards.

Flare-Skid - 12"

- The unit is designed with the mindset that the vent line and vent line fittings can be carried together. This provides a safer method of transporting pipe and fittings as well as creating a more efficient load during the rig moves.

- During transport, the flare is mounted and properly secured to pipe clamps on the skid

- The skid also has a mounted 12” Full-Port Check Valve. This check-valve not only provides the intended safety factor of protecting the entire system, in the event a flare flashes back into the vent line; but the check-valve is also properly sized, to give a full 12” of flow for gas to pass through the system. Unlike the competition, this system does not create unnecessary back-pressure on the well-bore allowing more efficient and safer drilling

- The flare is provided with a 2” venturi system to ensure gas is pulled to the flare to be effectively burned-off. An optional air pressure regulator is available to ensure a consistent and constant air pressure is maintained on the unit.

- Other available systems that can be installed on the flare system include gas detection, ignition verification, and flame monitoring

Mud Vent Valve

Patent No. US 11,346,167 B2

AIR-ACTUATED LO-TORQUE VALVE WITH MANUAL OVERRIDE

LO-TORQUE VALVE CONNECTIONS 2” 1502 H.U.

OPERATED REMOTELY

POWER REQUIREMENTS: 110VAC, 80PSI AIR

DESIGN

Uses the same style and size of Lo-Torque valve that is currently being used, Therefore no modifications are required for installation.

SAFE

The relief is valve airactuated, this removes the employee from having to manually operate the valve under pressure. The actuator comes with a visual indicator to show if the valve is in the “open” or “closed” position.

EFFICIENT

The control box is conveniently located in the Driller’s doghouse and is operated by the driller. This allows faster connections, removes wait times and elliminates the chance of miscommunication and errors.

Electric-Actuated Choke & Panel

PACKAGE INCLUDES ELECTRIC-ACTUATED CHOKE AND PANEL SYSTEM.

PRIMARY POWER IS 110VAC WITH BATTERY BACKUP AND MANUAL OVERRIDE.

3 1/16”- 10M STYLE DRILLING CHOKE WITH ELECTRIC ACTUATOR

•MAY BE OPERATED LOCALLY OR BY REMOTE ON THE CHOKE PANEL LOCATED IN THE DRILLER’S DOGHOUSE

•SYSTEM IS INDEPENDENTLY OPERATED OUTSIDE OF OTHER RIG PRESSURE CONTROL SYSTEMS. IN THE EVENT OF COMPLETE RIG FAILURE, THE WC CHOKE SYSTEM WILL STILL BE OPERATIONAL

•CHOKE PANEL CAN BE MOVED AROUND DOGHOUSE AS NEEDED. IT IS SIZED TO FIT THROUGH A STANDARD MAN-DOOR

•ELECTRIC GAUGES ARE CALIBRATED TO +/-10 PSI

• NOT AFFECTED BY WEATHER OR FLUID LEAKS

STROKE COUNTER

Stroke Counter

Monitors up to 4 mud-pumps, digital display with push-button selections. There are no moving parts, the pump counters are installed in the inspection plates and operated electromagnetically, powered by battery with at least a two-year lifespan.

Eco Tank & Flare Stack

Eco Tank*

Last line of defense preventing “fines” from entering the flare stack.

Flare Stack with Venturi Line*

Negative pressure to evacuate hazardous gasses away from the rig

*INCLUDED IN THE SEPARATOR PACKAGE

Eco-Tank - 12"

- Vessel is a coded Section 8 ASME vessel

- Unit is installed inline with the vent line to mitigate the release of water/dust/cuttings material through the flare stack during normal drilling operations.

- Unit has the capability to have sensors installed that can monitor the tank level as well as the pressure on the unit during use. These sensors also have the capability to be monitored through the Pason/Totco system on the rig

- If monitoring indicates the level is to high, a 4” drain is available to use to empty the unit

- Also installed on the unit is a 150psi pressure-safety valve (PSV); in the event a portion of the vent line or the unit itself is plugged off by unforeseen material. This PSV will allow any pressure build-up in the system to be vented to atmosphere.

- Also available is an 8” vent line system- most seen size in the air-drilling industry, however, this vessel is not coded; but these vessels are inspected by a third-party inspection company and are certified under API 510 standards.

Flare-Skid - 12"

- The unit is designed with the mindset that the vent line and vent line fittings can be carried together. This provides a safer method of transporting pipe and fittings as well as creating a more efficient load during the rig moves.

- During transport, the flare is mounted and properly secured to pipe clamps on the skid

- The skid also has a mounted 12” Full-Port Check Valve. This check-valve not only provides the intended safety factor of protecting the entire system, in the event a flare flashes back into the vent line; but the check-valve is also properly sized, to give a full 12” of flow for gas to pass through the system. Unlike the competition, this system does not create unnecessary back-pressure on the well-bore allowing more efficient and safer drilling

- The flare is provided with a 2” venturi system to ensure gas is pulled to the flare to be effectively burned-off. An optional air pressure regulator is available to ensure a consistent and constant air pressure is maintained on the unit.

- Other available systems that can be installed on the flare system include gas detection, ignition verification, and flame monitoring

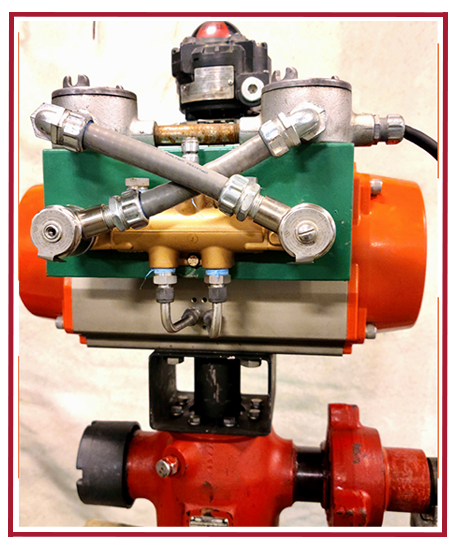

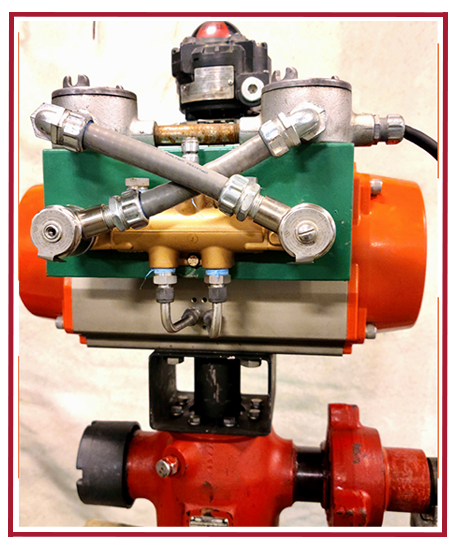

Mud Vent Valve

Patent No. US 11,346,167 B2

AIR-ACTUATED LO-TORQUE VALVE WITH MANUAL OVERRIDE

LO-TORQUE VALVE CONNECTIONS 2” 1502 H.U.

OPERATED REMOTELY

POWER REQUIREMENTS: 110VAC, 80PSI AIR

DESIGN

Uses the same style and size of Lo-Torque valve that is currently being used, Therefore no modifications are required for installation.

SAFE

The relief is valve airactuated, this removes the employee from having to manually operate the valve under pressure. The actuator comes with a visual indicator to show if the valve is in the “open” or “closed” position.

EFFICIENT

The control box is conveniently located in the Driller’s doghouse and is operated by the driller. This allows faster connections, removes wait times and elliminates the chance of miscommunication and errors.

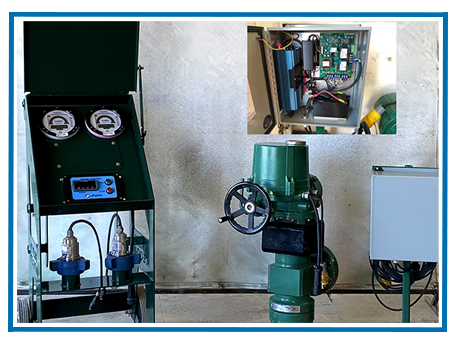

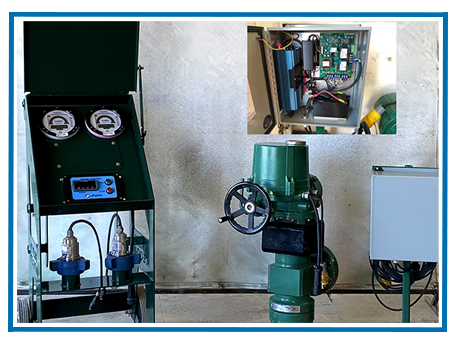

Electric-Actuated Choke & Panel

PACKAGE INCLUDES ELECTRIC-ACTUATED CHOKE AND PANEL SYSTEM.

PRIMARY POWER IS 110VAC WITH BATTERY BACKUP AND MANUAL OVERRIDE.

3 1/16”- 10M STYLE DRILLING CHOKE WITH ELECTRIC ACTUATOR

•MAY BE OPERATED LOCALLY OR BY REMOTE ON THE CHOKE PANEL LOCATED IN THE DRILLER’S DOGHOUSE

•SYSTEM IS INDEPENDENTLY OPERATED OUTSIDE OF OTHER RIG PRESSURE CONTROL SYSTEMS. IN THE EVENT OF COMPLETE RIG FAILURE, THE WC CHOKE SYSTEM WILL STILL BE OPERATIONAL

•CHOKE PANEL CAN BE MOVED AROUND DOGHOUSE AS NEEDED. IT IS SIZED TO FIT THROUGH A STANDARD MAN-DOOR

•ELECTRIC GAUGES ARE CALIBRATED TO +/-10 PSI

• NOT AFFECTED BY WEATHER OR FLUID LEAKS

STROKE COUNTER

Stroke Counter

Monitors up to 4 mud-pumps, digital display with push-button selections. There are no moving parts, the pump counters are installed in the inspection plates and operated electromagnetically, powered by battery with at least a two-year lifespan.